Published: 27/05/21 15:33 Categories: Microbiology

Dairy, beer and wine production was the starting point for the use of fermentation processes. However, this technology has advanced to such an extent that nowadays it can undertake large-scale production of essential medication such as vaccines.

Fermentation processes and bioproducts

Generally, products obtained by means of industrial fermentation or bioprocesses can be classified into metabolites (acetic and lactic acid), secondary metabolites (penicillin, streptomycin) and enzymes (amylases, pectinases and restriction endonucleases). The pharmaceutical industry carries out these fermentation processes for the production of antibiotics, diagnosis agents such as monoclonal antibodies and enzymes, enzyme inhibitors, steroids, and, as mentioned above, vaccines.

Even if traditional fermentation processes for obtaining food and beverages are still relevant for products available on the market, biotechnological developments have opened the door for high technological value molecule production using microbial vehicles as well as animal and plant cells.

For this purpose, it is necessary to replicate the production cells in a fermentation medium. At first sight, this may seem an irrelevant part of the bioprocess, but it is essential for the operation as it directly influences end product yield.

The importance of the fermentation medium

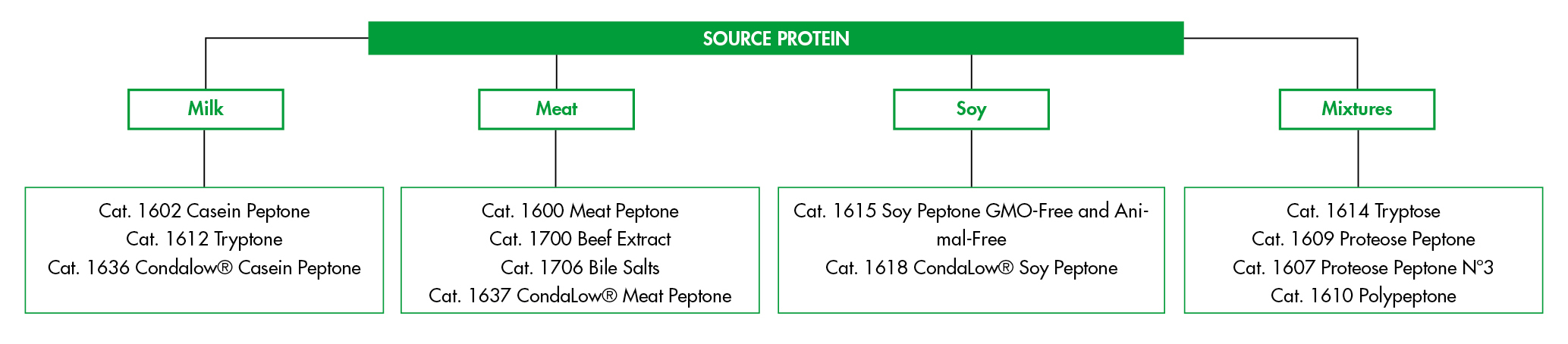

Medium composition and, therefore, its nutritional value, is a key element for successful fermentation. Adequate nitrogen compound dosing through peptones is particularly important, with meat, dairy and soybean extracts and hydrolysates being the most common.

It is essential to choose the appropriate protein source and hydrolysis method, as they will determine nutritional quality. In addition, it is also advisable to reinforce development with nutritional supplements made of peptones from mixed sources and different hydrolysis degrees.

In cell cultures, high endotoxin levels can affect and ruin the process. To avoid this, we offer our new line of CondaLow® peptones as a solution.

To learn more about our products, click on the image.

One of Condalab's identity mark is the manufacture of our own raw material, thus controlling end products and guaranteeing high consistency and performance across batches. Do not hesitate to contact us for further information.

Condalab Says YES to the World’s Leading Lab Trade Fair: Analytica 2026

Condalab Says YES to the World’s Leading Lab Trade Fair: Analytica 2026

CONDALAB to Exhibit at WHX Labs Dubai 2026

CONDALAB to Exhibit at WHX Labs Dubai 2026

Food fraud: How do we detect it?

Food fraud: How do we detect it?

Visit Us at MEDICA 2025 – Discover Our Precise Detection Solutions

Visit Us at MEDICA 2025 – Discover Our Precise Detection Solutions

PCR: The Technique Revolutionizing Rapid Detection in the Food Industry

PCR: The Technique Revolutionizing Rapid Detection in the Food Industry