Published: 02/08/24 11:55 Categories: Microbiology

When we think about obtaining high growth in a microbiological culture at a low price, hydrolysates are the best option. There are multiple alternatives depending on the raw material and the process of obtaining it, but one of the best known and most reliable is yeast extract.

Production: origin and method

But what exactly is it? Yeasts are a type of eukaryotic microorganisms of the fungi kingdom, relatives of molds and mushrooms.

Its extract is obtained by a process called autolysis, in which the temperature is increased until the cells die, and their own enzymes begin to digest their internal contents, this includes their internal structures, organelles, genetic material and proteins. In digestion, the cell walls are also broken, releasing all this mixture into the medium.

Next, a series of purifications and filtrations are carried out to obtain the content of the autolysate of the medium, also removing the remains of the cell wall. The process results in a product with a high nutritional value, ideal for human or animal food or for the cultivation of other species of microorganisms.

As for its history, in 1857 Louis Pasteur discovered that yeasts were responsible for fermentation in foods such as bread or alcoholic beverages.

20 years later, greater knowledge of enzymes and their effects led to the production of the first extracts, both yeast and meat, initially as flavorings. And it wasn't until 1881 that the idea of including yeast extract as an ingredient for the formulation of a bacterial culture media was forged.

Key factor in microbiological growth

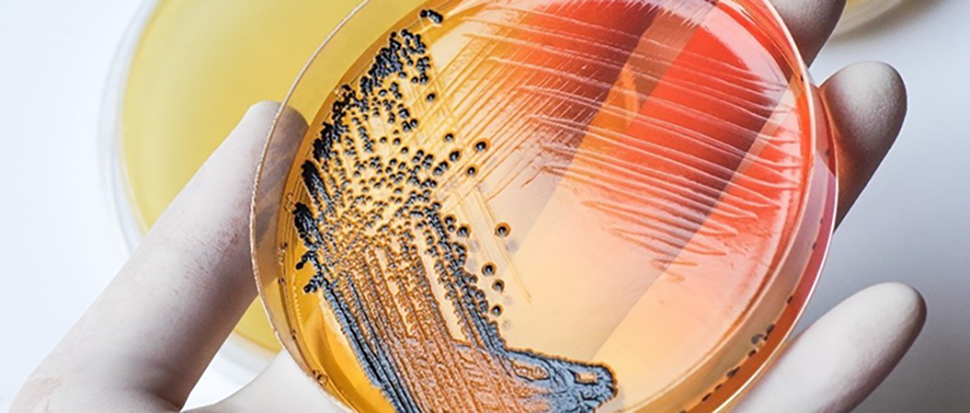

This bio-ingredient is a common component when producing a microbiological culture medium. The use of these media is varied:

- Clinical, to diagnose the presence of certain pathogens

- Sanitary, to find contamination in food and water

- Quality control, to ensure the sterility of the facilities and products that require it

- Fermentative, the synthesis of biological molecules through microorganisms

The range of fermentative processes is very wide, but in those where cell density is sought is where yeast extract shines. Its carbohydrate and amino acid content allows rapid cell growth, but it is also one of the few hydrolysates with a high value of B vitamins. It is also worth noting that it is a non-animal ingredient.

Some examples in the industry are the production of biostimulants, where a high concentration of microorganisms is required at a low cost; synthesis of antibiotics, especially in the most common and oral route; obtaining probiotics, another type of product that is based on a live microorganism.

At Condalab we offer a wide selection of microbiological culture media, while giving the possibility of directly acquiring the bioingredients used, to design your own media.

If you want to know more about our hydrolysates, visit our news about peptone protean nº3.

Condalab Says YES to the World’s Leading Lab Trade Fair: Analytica 2026

Condalab Says YES to the World’s Leading Lab Trade Fair: Analytica 2026

CONDALAB to Exhibit at WHX Labs Dubai 2026

CONDALAB to Exhibit at WHX Labs Dubai 2026

Food fraud: How do we detect it?

Food fraud: How do we detect it?

Visit Us at MEDICA 2025 – Discover Our Precise Detection Solutions

Visit Us at MEDICA 2025 – Discover Our Precise Detection Solutions

PCR: The Technique Revolutionizing Rapid Detection in the Food Industry

PCR: The Technique Revolutionizing Rapid Detection in the Food Industry