Published: 25/11/21 12:54 Categories: Microbiology

Industrial fermentation is based on cell cultures to obtain end products, which can be either the biomass itself or the metabolites produced by the cells. Chemically defined media are used to obtain these products in the highest possible concentration, quality and safety. These media are usually supplemented with peptones, products of high nutritional value and nitrogen assimilable compounds, improving growth and bioproduction yields.

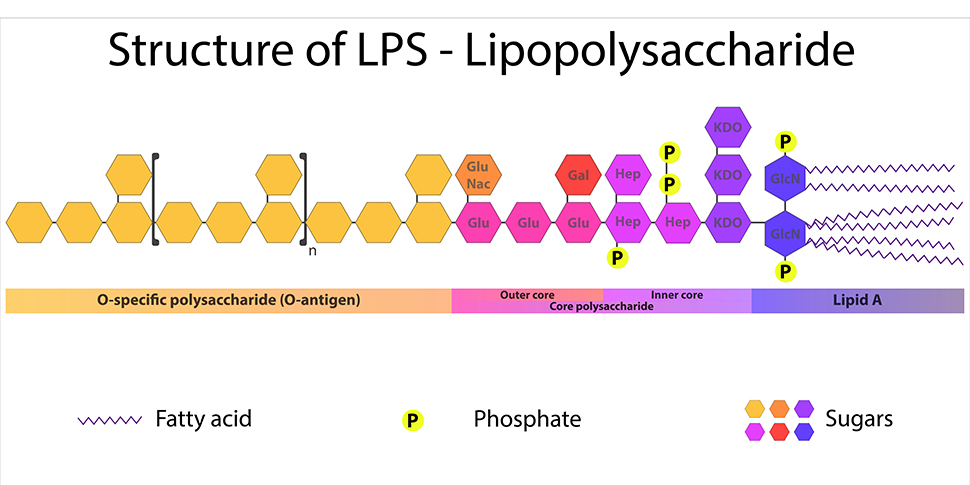

Endotoxins

However, these culture media contain a number of lipopolysaccharide fragments, known as endotoxins, that pose a huge obstacle to these purposes. Endotoxins are, furthermore, small, very stable and hard to eliminate molecules, so they accumulate in the process. This bioaccumulation can lead to various adverse effects in the culture:

- Lower cell growth

- Anomalous growth

- Lower yield of production of metabolites of interest

In industrial bioprocesses in which cell cultures are used to obtain a secondary metabolite (cell product) or even the biomass itself, final product quality is vital for its success and profitability. Endotoxins represent a major threat to the stability and quality of it and, therefore, to the industry.

However, it does not only affect the cells in culture but also the end consumer, posing a great risk to public health due to its presence in certain concentrations in the final product (vaccines, biostimulants, etc.), as it can generate an exacerbated immune response.

Condalow® peptones

Condalab unveils its new line of low endotoxin peptones: Condalow®. They not only contain less than 200 EU/g but also maintain higher concentrations of micro and macronutrients compared to ultrafiltered peptones available on the market. This is because when ultrafiltration is applied to the peptones, they not only filter out endotoxins, but also high nutritional value molecules, which does not occur in our Condalow® peptones, thanks to our revolutionary production system.

We offer three types of peptones in this line:

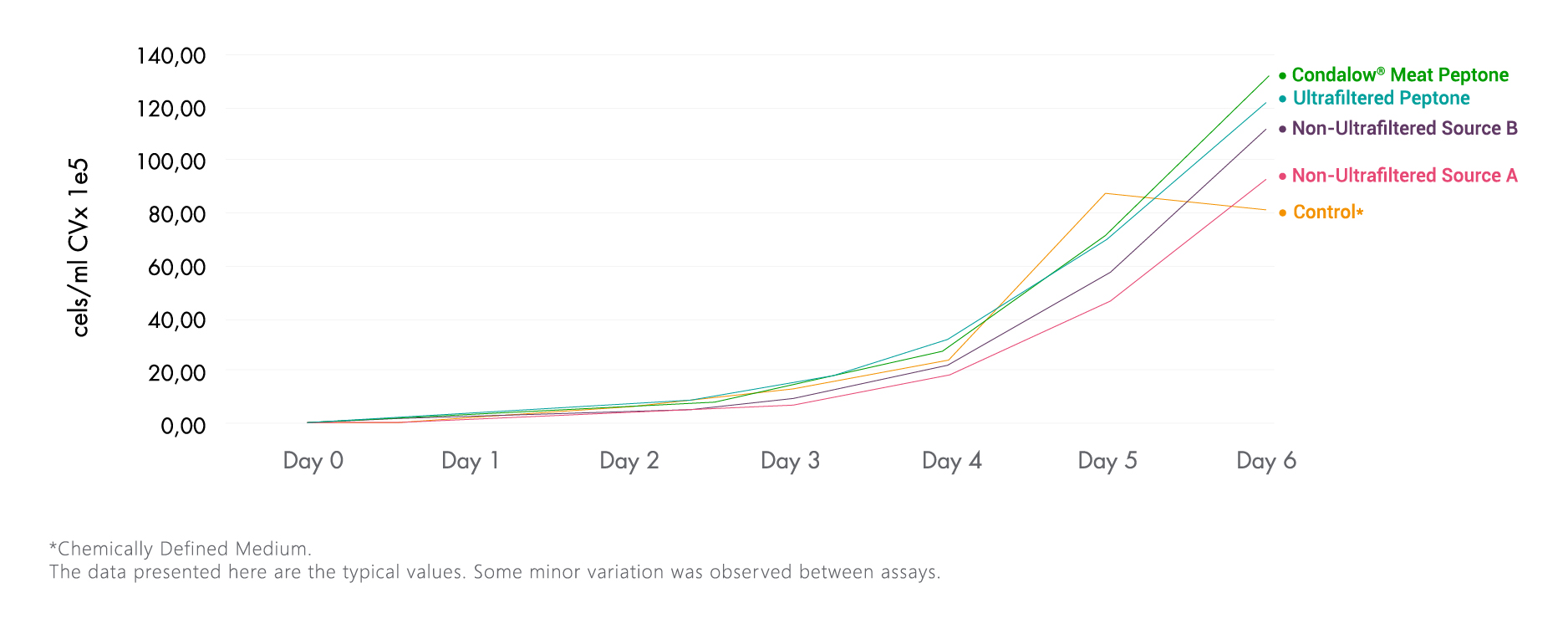

- Condalow® Meat: Compared with ultrafiltered (UF) and non-ultrafiltered (N-UF) peptones. Condalow® Meat offers enhanced cell growth (cell line: CHO). N-UF peptones offer good but unreliable data, as these batches are of very low consistency. Even so, they are still lower quality results compared to competing UF peptones, even more so with Condalow® Meat.

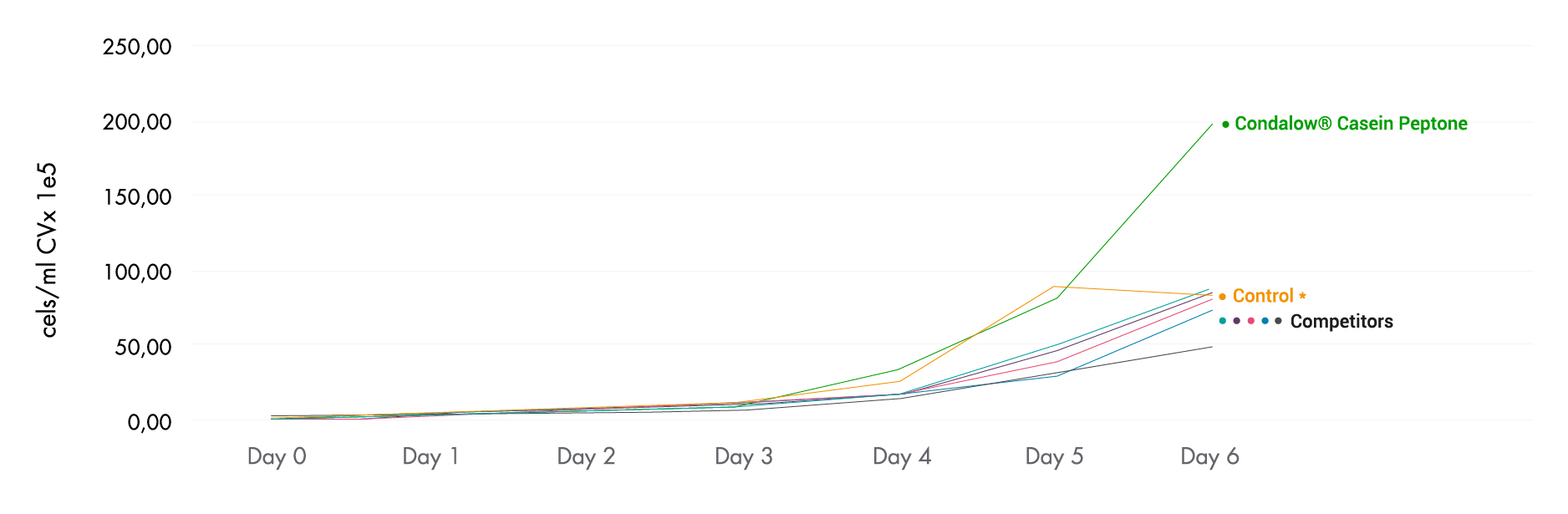

- Condalow® Casein: UF casein peptones are not available on the market. In growth terms, Condalow® Casein offers much higher values than assessed competing values, demonstrating the enormous effect it has on cells and their growth.

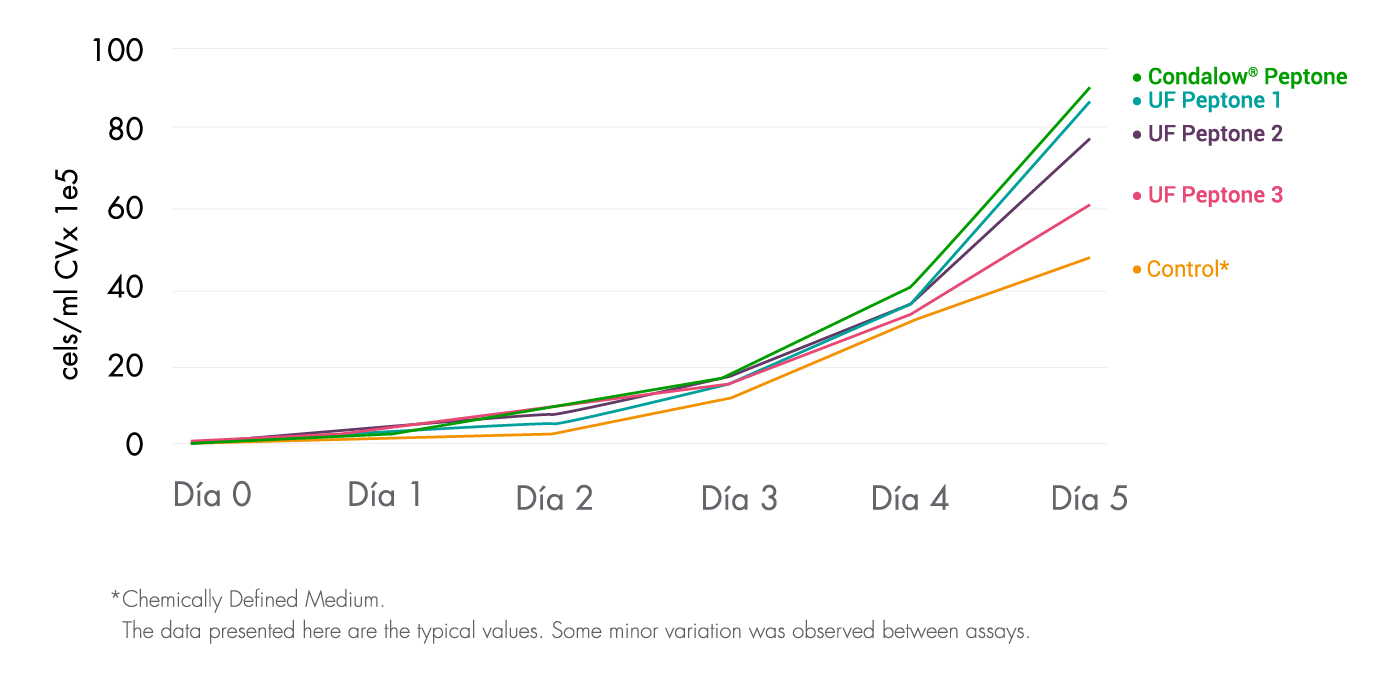

- Condalow® Soy: Again, it shows better cell growth results compared to competing UF peptones. In addition, as it is Animal-Free and GMO-Free, the advantages of facilitating the process of obtaining biomolecules are gained.

Therefore, we recommend adding 1g/L of this peptone in your processes.

Therefore, our Condalow® peptones offer an endotoxin concentration of under 200 EU/g, lower values compared to those offered by non-ultrafiltered peptones, in addition to maintaining higher amounts of micro and macronutrients compared to competing ultrafiltered peptones. Harmful effects are reduced, while beneficial effects are maintained.

If you want to know all the details about the studies carried out on our Condalow® peptones, you can download the Application Notes or consult our webinar about it in our CondalabTalks Innovation Series.

Food fraud: How do we detect it?

Food fraud: How do we detect it?

Visit Us at MEDICA 2025 – Discover Our Precise Detection Solutions

Visit Us at MEDICA 2025 – Discover Our Precise Detection Solutions

PCR: The Technique Revolutionizing Rapid Detection in the Food Industry

PCR: The Technique Revolutionizing Rapid Detection in the Food Industry

How Culture Media Ensure the Safety, Efficacy, and Quality of Medicines

How Culture Media Ensure the Safety, Efficacy, and Quality of Medicines

Meeting us at MEDLAB MIDDLE EAST 2025

Meeting us at MEDLAB MIDDLE EAST 2025